Bearcon Industrial provides precision lagging and insulation services to support temperature control, energy efficiency, and compliance across industrial facilities.

From clean rooms to plant infrastructure, we deliver tailored solutions that reduce energy waste, improve system performance, and meet regulatory standards.

We're trusted in environments where safety and cleanliness are mission-critical.

Trusted by leading companies across manufacturing, pharmaceuticals, and public sectors.

Proper insulation plays a vital role in industrial environments by helping maintain thermal stability, preventing energy loss, and protecting both equipment and personnel. Without effective lagging and insulation, temperature-sensitive processes become harder to manage, operating costs rise, and energy compliance goals become harder to reach.

Effective insulation significantly reduces heat loss, minimises surface condensation, and enhances overall operational efficiency. It helps maintain internal temperatures, lowers fuel usage, and supports the long-term performance of HVAC, pipework, and process equipment - all while reducing carbon footprint and utility costs.

We install insulation in a wide range of industrial and commercial settings, including pharmaceutical clean rooms, manufacturing & processing facilities, food and beverage facilities, and agricultural buildings for livestock. Our solutions are customised for high-sensitivity areas, prioritising hygiene, performance, and ease of maintenance.

We offer a range of insulation types to suit different industrial needs. Each solution is tailored to improve performance, reduce energy loss, and support compliance.

Thermal jackets are removable insulation covers designed for valves, steam pumps, flanges, and other irregular components where traditional insulation is difficult to apply. These jackets minimise heat loss, protect personnel from hot surfaces, and improve system efficiency in high-temperature environments.

We support pharmaceutical plants and clean rooms with hygienic, high-performance insulation that ensures temperature stability, contamination control, and regulatory compliance.

Insulation helps food and beverage facilities maintain strict temperature requirements, improve energy efficiency, and meet safety and hygiene standards reliably.

Lagging and insulation enhance energy performance in offices and commercial spaces, reducing operational costs while improving comfort and environmental certifications.

Proper insulation reduces heat loss in agricultural buildings, protecting equipment, livestock, and produce while improving overall energy efficiency and cost savings.

We help warehouses and cold storage facilities maintain consistent internal temperatures, reduce energy use, and ensure product quality and safety.

High-quality insulation in engineering and fabrication facilities helps maintain controlled environments, protects sensitive equipment, and enhances energy efficiency.

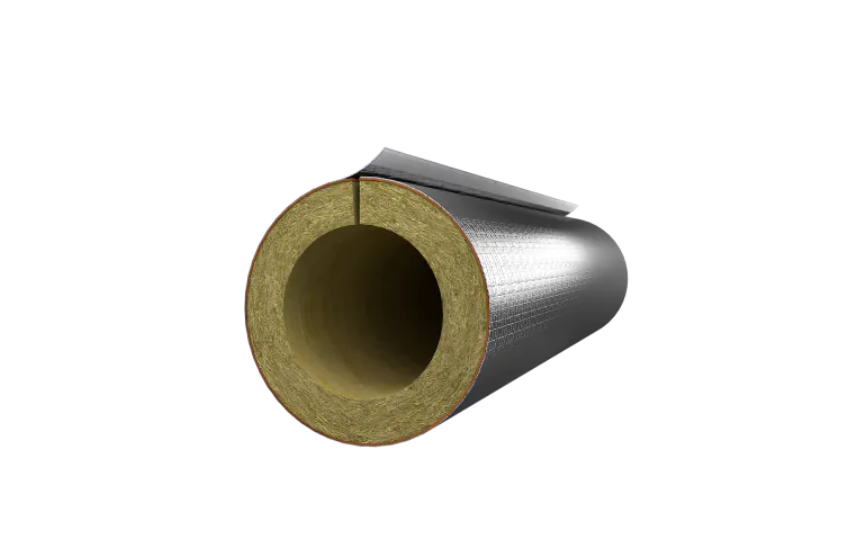

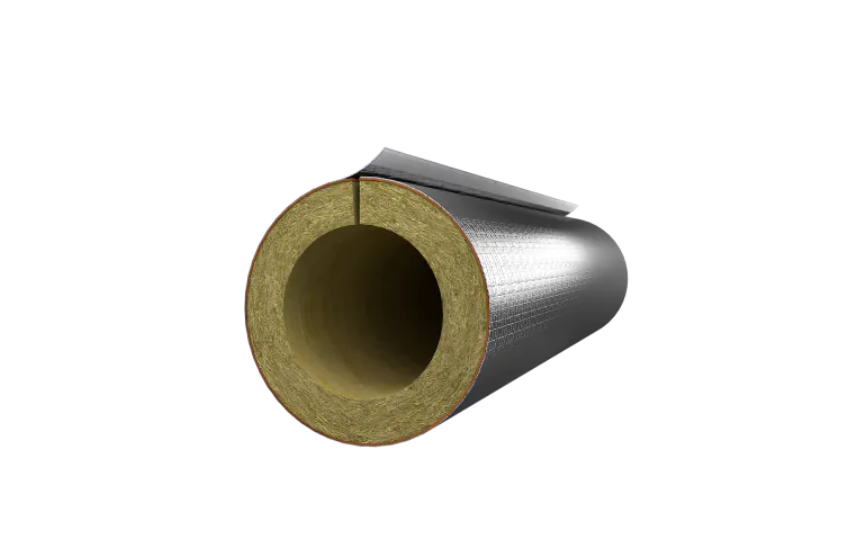

Lagging refers to the insulation applied to pipes, tanks, or ductwork to reduce heat loss, prevent condensation, and protect equipment. It’s especially important in industrial environments where energy efficiency and temperature control are critical.

We offer a range of insulation solutions including pipe lagging, duct insulation, T-Fit and T-Tube closed cell insulation for clean room environments, and mineral wool for high-temperature applications. We tailor each installation to the facility’s operational and compliance needs.

Yes. In many sectors, insulation is required to meet building regulations, energy efficiency standards, and health & safety guidelines.

Timeframes vary depending on the size and complexity of the facility. Small-scale installations can take a day or two, while larger projects may require phased work. We always aim to minimise disruption to your operations.

Absolutely. Proper insulation helps maintain consistent temperatures, meaning your systems don’t have to work as hard — which leads to reduced energy consumption and lower utility bills over time.

Yes. We have years of experience and are fully-trained to work in high-sensitivity environments such as pharmaceutical clean rooms and food-grade facilities. We use fully-approved materials and follow strict protocols to meet hygiene and compliance standards.

We use high-performance materials such as mineral wool, T-Fit & T-Tube closed cell insulation, nitrile rubber & Armaflex, and rigid foam boards. Material choice depends on the specific application, temperature range, fire rating, and hygiene requirements of the facility.

Yes. We provide ongoing maintenance, inspections, and replacement services to ensure your insulation continues to perform efficiently. This is especially useful for aging systems, regulatory audits, or facilities with strict temperature control needs.

We’re here to answer your questions, provide guidance, and help you find the right solution for your facility.